Strong energy savings. Up to 80% compared to versions without the 'free-cooling' device, real reduction in compressor working hours.

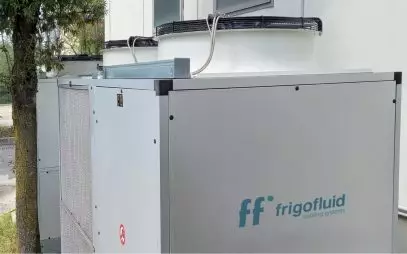

RW / EFC ax Liquid Free Cooling Chiller

for energy savingThe secret of this system is the combination of the refrigeration section and the free-cooling section depending on the time of day and year: the first mode allowed by these liquid chillers takes advantage of the normal operation of a refrigeration circuit, the second allows cold outside air to be directly conveyed to the fluid to be cooled: maximum efficiency, minimum energy use due to the clear separation between the two sections.

Optimising efficiency and energy. Thanks to the electronic control enabled by EC Brushless axial fans.

For high outside temperatures. Up to +40°C, with the possibility of adaptation according to customer requirements.

Turnkey solution. A single point of contact throughout the project, possibility of integration with further systems and ancillary plant components.

Quick pay-back. Pre-selection together with the customer, based on his project requirement.

Ready for remote monitoring. A serial port can be coupled to the machine for interface connection with a remote station.

Efficient and sustainable liquid chillers

RW / EFC series units automatically manage and combine three cooling modes depending on the current season and process fluid temperatures.

- Summer’ situation: RW. With a room air temperature above approx. +23 °C, the flow temperature is guaranteed by the operation of the compressors alone.

- Situation “middle season”: RW / EFC. With room air temperature between approx. +23°C and +15°C the supply temperature is guaranteed by the combined operation of compressors and free cooling section, this phase is identified as partial energy saving.

- Winter situation: EFC. With ambient air at a temperature of approx. +15°C below, the supply temperature is guaranteed thanks to the free cooling section alone, this phase is identified as total energy saving.

Manufactured in monobloc units integrating chiller technology with dry cooler technology, these liquid chillers offered by Frigofluid provide a clear separation between the free-cooling section and the chiller section. The suggested process fluid temperature values for this technology are between +10°C and +25°C.

In standard execution, ambient temperatures up to +40°C are permissible, but special fittings are available on specific request.

Tell us your needs

Focus free-cooling: efficiency and energy savings

The RW EFC ax series chillers, designed for free-cooling operation, guarantee important economic advantages, which can be seen directly in the reduction of energy costs.

There is also an indirect effect in terms of improved environmental impact through reduced CO2 emissions.

The technical solution proposed by Frigofluid provides a clear separation between the free cooling section and the chiller section. This allows, in comparison to other solutions on the market, which merely provide free-cooling in series with the condenser, the following results to be achieved:

- Exploitation of the entire energy-saving period even in partial mode at any room temperature, ensuring the best condensation on the freon side of the chiller. In contrast, other design choices force most of the savings to be foregone in favour of adequate condensation control.

- Lower energy use related to freon condensation fans. Conversely, other design choices force greater energy consumption on the condensation fans in the summer period as they are forced to overcome the aeraulic pressure drops caused by the presence of the free-cooling pack although not used due to the high ambient temperature.

- Given the above points, in addition to the energy advantages we obtain a real reduction in compressor working hours with a net increase in their life span.

Versions and types of accumulation available

- RWC ax: hermetic internal storage (possibility of connecting other power packs in parallel).

- RWA ax: internal storage at atmospheric pressure.

- RWE ax: for external storage.

Series components on all Frigofluid chillers

1. EC (electronic control) Axial Fans

2. Microchannel Condenser

3. Compressors

4. AISI 316 SS Plate Evaporator

5. Storage tank

6. Electronic Microprocessor for the hydraulic and Chilling Systems

EC (electronic control) Axial Fans

As standard over the entire production range. They guarantee high performance at top speed and control in the slowrunning range.

Microchannel Condenser

Featuring a wide exchange surface and subcooling system plus epoxy paint surface treatment as standard.

Compressors

Hermetic systems of “Scroll” type on all models in the catalog.

AISI 316 SS Plate Evaporator

Or tube-nest evaporator. With foam closecell thermal insulation.

Storage tank

In zinc-plated steel featuring close-cell foam insulation and a range of accessories: air exhaust, safety valve, discharge valve, fittings for level control.

Electronic Microprocessor for the hydraulic and Chilling Systems

Allowing control of the (glycol-added) water temperature and display of the chilling gas operating pressure with remote diagnostics possibility: an alpha-numeric display shows the unit’s working status. In the units with more than one compressor, the microprocessor controls their starts on a rotation basis in order to balance their operating hours.

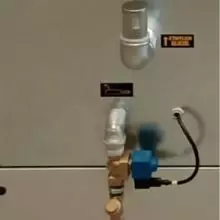

Manual By-Pass

An accessory designed for the function of adjusting the flow rate of water or water/glycol from a hydraulic circuit so as to obtain a working condition suitable for the chiller and its use. This adjustment is carried out by controlling the discharge pressure of the chiller pump.

Expansion Vessel Kit

An accessory designed for the function of containing changes in "hydrostatic" pressure in a type "C" (pressurized) hydraulic circuit due to changes in water and/or water/glycol liquid temperature.

Outdoor Kit

This is an accessory consisting of 3 elements that ensure IP 55 watertightness of the electrical panel and its components for outdoor installation without any canopy or other protection. With OPT 01250 a cover is applied on the electrical box that protects the gasket of the switchboard door.

RTU Modbus

Allows communication of data from our control panels with supervisory and/or other systems through a modbus communication but also OPC UA and PROFINET.

Automatic Loading

Hydraulic system aimed at controlling the filling from water or water/glycol of hydraulic circuits. Consisting of accessories and fittings, it is installed on RW power plants, RAW coolers, and systems in general.

Water Filter

Mechanical filter installed on the water inlet pipe to the chiller (return). The filter usually Y-type can be bronze for sections up to 2" ½ max 3", or spheroidal cast iron flanged for sections 3" and up.

Componenti di serie

Continous Saving in Plastic Moulding with Frigofluid Chillers

Frigofluid supplied a chiller with built-in free-cooling to a Veneto-based plastic moulding company as part of the expansion of its production system (addition of new presses). The consultancy covered not only the technical solution, but its incorporation into the plant's entire heating and air-conditioning system.

Read moreIndustry 4.0 Certified Frigofluid Chillers for Plastic Processing

Processes for Industry 4.0 and optimal interaction with previously installed chillers. This is how Frigofluid's products have convinced a company from Vittorio Veneto, which has been active in plastic moulding for 40 years.

Read moreFrigofluid Refrigeration Systems Serving the Circular Economy

A company producing plastic from waste material asked Frigofluid to supply an industrial chiller and an adiabatic dry cooler.

Read moreComponenti su richiesta

Preliminary Assessment

Customized Design

Custom Chillers and Turnkey Plants

Resources

Plants and components

Find out all Frigofluid's productsComparing Different Technologies

Find out all the different technologiesFind out more

All technical articlesOur Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.