Industrial chillers that optimise the use of resources

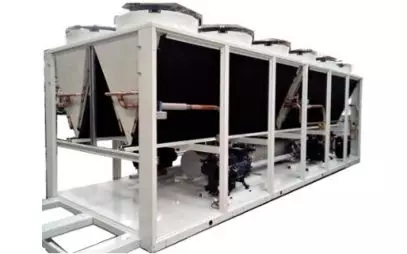

An increasingly attractive point for industry, also in the plastics moulding sector, is the possibility of industrial refrigeration performance with measurable savings in electrical energy: this is what Frigofluid’s RW EFC ax series process chillers make possible, which were also selected for a plastics moulding company in the Treviso area.

The main requirement was the refrigeration of plastic presses, taking into account a future expansion of the production site (with five presses).

As far as the optimal management of heat and cold was concerned, the client company had initially assumed the re-use of the machines’ condensation heat to heat the production areas: Frigofluid showed (data in hand) that it was more cost-effective to use the continuous savings allowed by free cooling, a mode of use incorporated in the RW EFC ax series.

Independent, brushless axial fans with electronic control of the operating parameters allow the highest possible energy savings.

There are three operating modes for the RW EFC ax industrial chillers (alternatives, depending on the season and time of day):

- RW central cooling with air condensation, which allows the set temperature to be maintained, even with ambient air temperatures higher than those of the process fluid, thanks to the work of the compressors.

- RW / EFC cooling by combined effect of chiller section and free-cooling section.

- EFC liquid cooling by driving only the fans of the EFC section, with very low electricity consumption. The suggested process fluid temperature values for this technology are between +10°C and +25°C. In standard execution, ambient temperatures of up to +40°C are permitted. Special designs are available on specific request.

The free-cooling chiller supplied to the Treviso company uses two refrigerant gas circuits. Total cooling capacity: 55.8 kWf.

Ask for information