The Refrigeration Cycle: how Refrigeration Works

The refrigeration cycle is the basis of all the refrigeration systems we find in our refrigerators and air conditioners, but also in industrial compression chillers. This process uses physical principles to transfer heat from one environment to another, thus maintaining controlled temperatures.

In this article we see how.

1. What is the refrigeration cycle?

In poche parole, il ciclo frigorifero è un ciclo termodinamico in cui un fluido refrigerante assorbe e rilascia calore in modo controllato. Questo permette al chiller industriale di estrarre calore da un sistema di processo per rilasciarlo altrove, abbassando così la temperatura. Su questo principio si basa la refrigerazione industriale (e non).

Questo processo avviene grazie al cambiamento di stato del refrigerante, che passa da gas a liquido e viceversa durante il ciclo.

Simply put, the refrigeration cycle is a thermodynamic cycle in which a refrigerant fluid absorbs and releases heat in a controlled manner. This allows the industrial chiller to extract heat from a process system and release it elsewhere, thus lowering the temperature. Industrial refrigeration (and non-industrial refrigeration) is based on this principle.

This process is accomplished by the change of state of the refrigerant, which changes from gas to liquid and vice versa during the cycle.

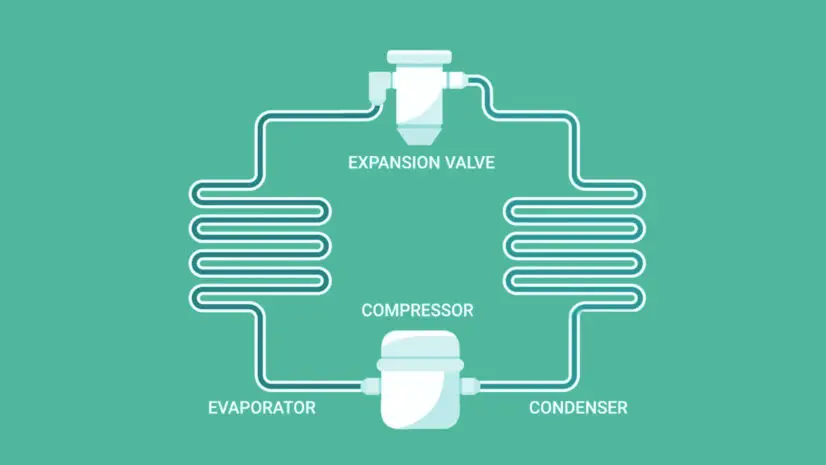

2. Stages of the refrigeration cycle

Here are the steps in the refrigeration cycle of a chiller.

- Refrigerant compression. The cycle begins with compression of the refrigerant, which is pressurized in the compressor. This step increases both the pressure and temperature of the gas, making it ready for the next stage of condensation.

- Condensation and heat transfer. The hot, pressurized refrigerant passes through the condenser, where it gives up heat to the external environment. During this process, the gas turns to liquid, reducing its heat energy.

- Expansion and pressure reduction. Once liquefied, the refrigerant passes through a lamination valve, where it undergoes a drastic drop in pressure and temperature, transforming into a mixture of liquid and vapor at low pressure.

- Evaporation and heat absorption. The refrigerant mixture enters the evaporator, where it absorbs heat from the environment to be cooled, thus completing the cycle. Heat absorption evaporates the liquid, which returns to a gaseous state ready to be compressed again.

- Cycle Repetition. After evaporation, the refrigerant gas returns to the compressor, and the cycle begins again, providing constant and efficient cooling.

3. Components of the refrigeration cycle

We have already seen in a separate article what the components of the refrigeration cycle are: let us give a quick summary here.

- The Compressor: the central part of the system. This is where the refrigerant is pressurized to begin the process. There are several types of compressors, including rotary, screw, and scroll, each with its own characteristics and advantages.

- The Condenser: heat exchanger. In this component, the refrigerant gives up heat to the external environment, allowing the change of state from gas to liquid. This part of the chiller is critical to ensuring high system efficiency.

- The Laminating Valve. Regulates refrigerant pressure, reducing it rapidly to allow evaporation. It is a key component for managing temperature and pressure within the system.

- The Evaporator: absorption area. In the evaporator, the refrigerant absorbs heat from the environment to be cooled, completing the refrigeration process. Here the refrigerant evaporates, removing heat from the surrounding air or a refrigerated liquid.

4. Types of refrigeration cycles

We have generally talked about “refrigeration cycle”: there are actually several types of refrigeration cycles, depending on the chiller or refrigeration machine, which differ more or less from a basic standard.

Let’s start with the compression refrigeration cycle: this is the most common refrigeration cycle, used in most industrial cooling chillers (as well as domestic refrigerators). It works thanks to a mechanical compressor that pushes refrigerant through the cycle.

Then there is the absorption cycle: in this type, instead of a mechanical compressor, an absorption fluid is used for the refrigerant. This system is frequently used in cogeneration: in this case we speak of an absorption chiller.

Finally, there is also a magnetization cycle, based on the magnetocaloric effect. This cycle uses the magnetic properties of certain materials to generate cooling. It is still an experimental technology but promising in terms of efficiency and sustainability.

5. Efficiency and sustainability

But what are the factors that determine the higher or lower energy efficiency of a chiller and refrigeration cycle?

Modern refrigeration systems aim to minimize energy losses by relying on available technologies. In some applications, the use of inverters can be a solution for efficiency. Remote control is also another technical breakthrough to manage and optimize the operating parameters of the machinery: at all times, even when not present.

On the other hand, as technologies have evolved, environmentally friendly refrigerants have been introduced that improve efficiency and reduce ecological impact: in this sense, EU legislation has led the way in introducing low-GWP refrigerant gases such as R32 and 290.

Ask for InformationResources

Plants and components

Find out all Frigofluid's productsComparing Different Technologies

Find out all the different technologiesFind out more

All technical articlesOur Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.