Examples of industries: plastics processing, moulding, moulding, extrusion, rubber processing, mixers and moulding presses.

Industrial Chillers for Plastics and Rubber

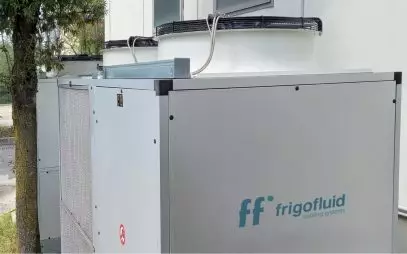

Plastics processing is a heterogeneous sector. Frigofluid’s industrial chillers for plastic and rubber are appreciated in this sector for their reliability and precision. Customers can also request turnkey refrigeration systems complete with refrigeration unit, secondary coolers and other accessories.

Main requirements: heat dissipation with different operating temperatures, hydraulic circuit types and cooling water operating pressures.

Industrial chillers for plastics and rubber: at a glance

Here are some of the activities in plastics processing that require heat dissipation by means of industrial chillers:

- injection or rotation moulding,

- blow moulding,

- extrusion,

- thermoforming.

The utilities requiring refrigeration, cooling or even temperature control are therefore of a different nature depending on the type of department. Therefore, heat management systems can be identified in the following components

- the mould (steel or aluminium),

- the water/oil heat exchanger,

- the calender or cylinder.

The main differences that distinguish the application of refrigeration to the above-mentioned activities therefore concern the operating temperatures, the type of hydraulic circuit and the operating pressures of the cooling water.

Finally, refrigeration for rubber is mainly applied in the closed circuit cooling of moulding presses.

Ask for information

Turnkey Industrial Refrigeration Plants

A refrigeration system is more than a single chiller: heat exchangers, hydraulic connections, additional cooling devices also come into play to support your production process.

RW / EFC ax Liquid Free-Cooling Chiller

The secret of this system is the combination of the refrigeration section and the free-cooling section depending on the time of day and year: the first mode allowed by these liquid chillers takes advantage of the normal operation of a refrigeration circuit, the second allows cold outside air to be directly conveyed to the fluid to be cooled: maximum efficiency, minimum energy use due to the clear separation between the two sections.

PAD-V Adiabatic Cooler Condenser

Adiabatic liquid coolers and gas condensers PAD-V series are offered where the focus is particularly on rational use of water and energy thanks to a dual operating principle, during hot and cold seasons, and thanks to the control panel that optimizes system operating parameters.

Some Frigofluid projects

Saving Energy with a Turnkey Refrigeration System

A large plastics processing company needed to renew its refrigeration plant in its entirety. During the summer shutdown and the concomitant production stoppage, we built a turnkey refrigeration plant complete with: chillers, adiabatic coolers, heat exchanger, electrical panels and storage tank.

Read moreManufacturing Brand chooses Frigofluid Turnkey Refrigeration Systems

Chillers, coolers, temperature controllers, accessories and installation services for an Italian designer objects company.

Read moreContinous Saving in Plastic Moulding with Frigofluid Chillers

Frigofluid supplied a chiller with built-in free-cooling to a Veneto-based plastic moulding company as part of the expansion of its production system (addition of new presses). The consultancy covered not only the technical solution, but its incorporation into the plant's entire heating and air-conditioning system.

Read moreDo you already know your plant engineering requirements?

Tools to help you choose

Preliminary Assessment

Customized Design

Custom Chillers and Turnkey Plants

Our Newsletter

Subscribe to the Frigofluid newsletter: stay up-to-date on technical solutions for industrial refrigeration and cooling and get to know our offer.