Description of industrial dry coolers

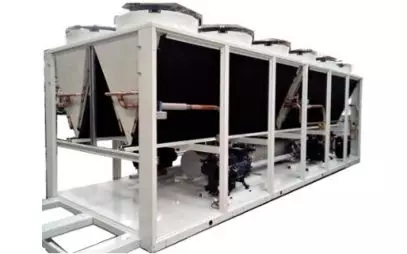

Dry coolers, or air coolers (or even dry cooling systems) dispose of heat in process fluids through the sole use of outside air and the energy required to convey it into the system.

They are closed-loop cooling systems: the fluid to be cooled is circulated within a finned heat exchanger, while one or more fans move ambient air through the fins.

Here is a list of the advantages of dry coolers over other cooling systems.

- Ease of installation and maintenance.

- Closed-loop operation, which prevents contamination of the fluid to be cooled with outside air.

- Absence of water consumption, an important factor in water shortage areas.

There are two main configurations of dry cooler.

- “Table-shaped”: this is an exchanger with a front arrangement of finned coils, typically for small to medium sizes.

- “V-shaped”: an exchanger with a V-shaped arrangement of finned coils, which maximizes the heat exchange surface area and is recommended for high air flow rates.

Ask for Information