Different refrigeration systems for different process lines

The optimal selection of different refrigeration systems, depending on the different production lines served, brings a double benefit. On the one hand, the most obvious economic benefit is the utilisation of resources according to the actual needs of the plant and individual process, with the resulting ‘cuts in bills’. Furthermore, this optimisation of water and energy supports the environmental sustainability to which companies and consumers are rightly becoming increasingly attentive.

An environmentally sustainable plastics company in Veneto has also opted for a dual system for several lines:

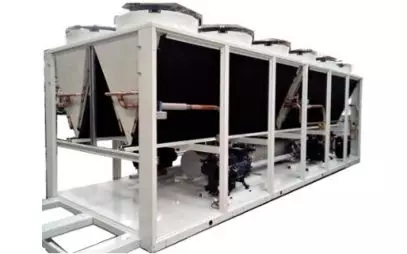

- an RWC EFC ax chiller. The free-cooling device of this refrigeration system allows, in cold periods and when automated by means of a control panel, direct cooling of the ambient air. Energy savings of up to 80% compared to chillers without such a device can be calculated.

- an adiabatic dry cooler PAD-V. This is an optimal system for average fluid outlet temperatures (for which a chiller is not required). In addition, the possibility of changing from the ‘standard’ dry cooling mode to the adiabatic pre-cooling mediated mode has an advantage: the optimal balance of performance and resource savings, with considerable water savings.

In addition to these two systems, Frigofluid supplied the customer with the hydraulic system, thus positioning itself as the single point of contact for industrial refrigeration with the company.

Ask for information