How turnkey refrigeration can save a manufacturing company resources

Five machines with three different types of operation, all however designed and installed in such a way as to allow energy saving and resource utilisation by automatically utilising all the hours of actual operational need. Hydraulic accessories, pump kits and storage tanks, installation services (including disposal of degraded process fluid) complete the supply of this turnkey refrigeration system.

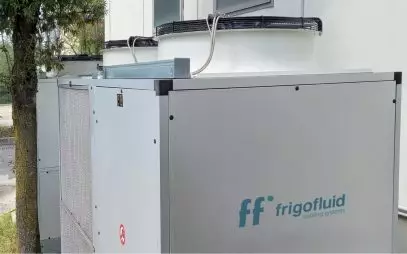

The customer company is based in Monza Brianza and operates in the production of high-end plastic food containers.

We have renewed the entire fleet of machines currently in use by replacing and updating them with:

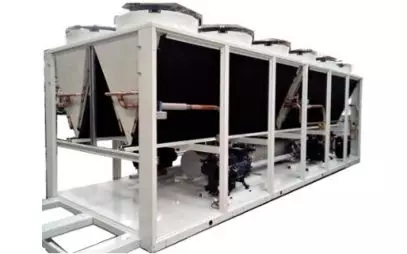

- no. 2 air-cooled chillers RWE 624/4 ax ST,

- no. 1 central dry cooler RAW 360/E

- no. 2 adiabatic dry coolers PAD-V S 3/6 Q.

Total installed cooling capacity: 1,910 kWf.

The refrigeration system thus integrated replaces high-performance power stations with uninterrupted operation: the total energy saving expected is approximately 20%, thanks to the special features of the individual refrigeration and cooling systems.

In fact, Frigofluid chillers have remote control as standard: this means that the customer company can decide to monitor the operating parameters also from the company management system. On the other hand, the dry cooler allows energy saving “by default” thanks to the free-cooling action: i.e. cooling through the direct action of ambient air on the heat exchange coils. The adiabatic dry cooler, on the other hand, allows optimisation of the resources used by switching (depending on the parameters set on the control panel) from a purely air mode to another with pre-cooling by means of very short wetting cycles.

Ask for information